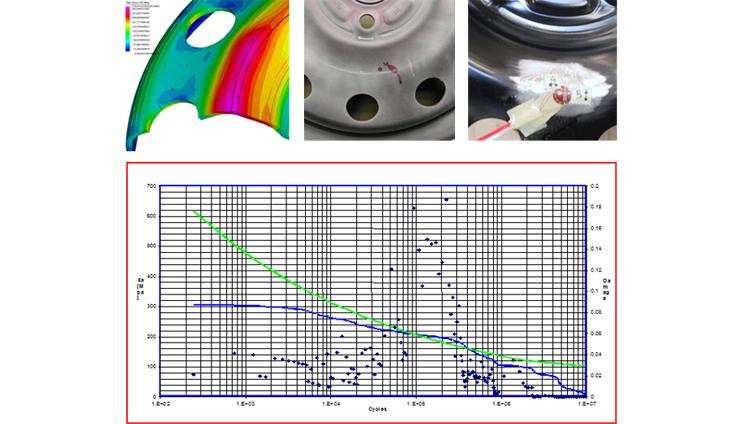

The strain-gauge analysis allows the evaluation of the surface stress of a component subjected to a load by measuring the local surface strain of the material.

This experimental step is essential to correlate the results of the FEM simulation, in particular in the critical areas of the component, in order to validate the design phase. The application points of the strain gauges and the type of test to be performed are dependent on the stress distribution identified by calculation and on the mission profile of the wheel.

It is also possible to perform the study on vehicle brakes and hubs. The strain-gauge test method performed in combination with the biaxial machine provides a complete overview of the stress distribution on the wheel during a drive.

Users

Wheels manufacturers

Hubs manufacturers

Brakes manufacturers

Cars manufacturers

Light commercial vehicles manufacturers

Components manufacturers

Instruments / Test Machines

Strain gauges type : 120 Ω, mono-axial from 1 to 3 mm and bi-axial

Data acquisition system:

Vishay A2 MC 8 (main unit)

Vishay A2 SG 8 BW (strain gauge card)

NI USB 6009 - 14 bit with 8 digital and 8 analogue input channels.

Applications

Measurements performed for the majority of automobile and light commercial vehicle manufacturers.